For nearly forty years, the Orbis Flying Eye Hospital has criss-crossed the world, bringing eye care to thousands of patients worldwide — and training up generations of eye specialist doctors on the ground to carry on its work after the flying teaching hospital takes off for its next destination.

Now on its third generation of aircraft — first a Douglas DC-8, later a DC-10, and now an upgraded MD-10 — this ex-freighter is ready and waiting to resume operations after COVID-19 travel restrictions lift. But behind the incredible feat that is fitting an eye hospital inside a commercial airliner, how is the aircraft itself kept in tip-top shape? Bruce Johnson, Orbis’ director of aircraft operations, tells us that it’s all about the MRO.

“We have a very experienced maintenance team with MD10 experience that are aboard the aircraft on all flights as well as during the medical programs,” Johnson explains. “We use several MROs to provide the heavy scheduled maintenance checks with the unscheduled daily maintenance being provided by our own onsite Orbis mechanics.”

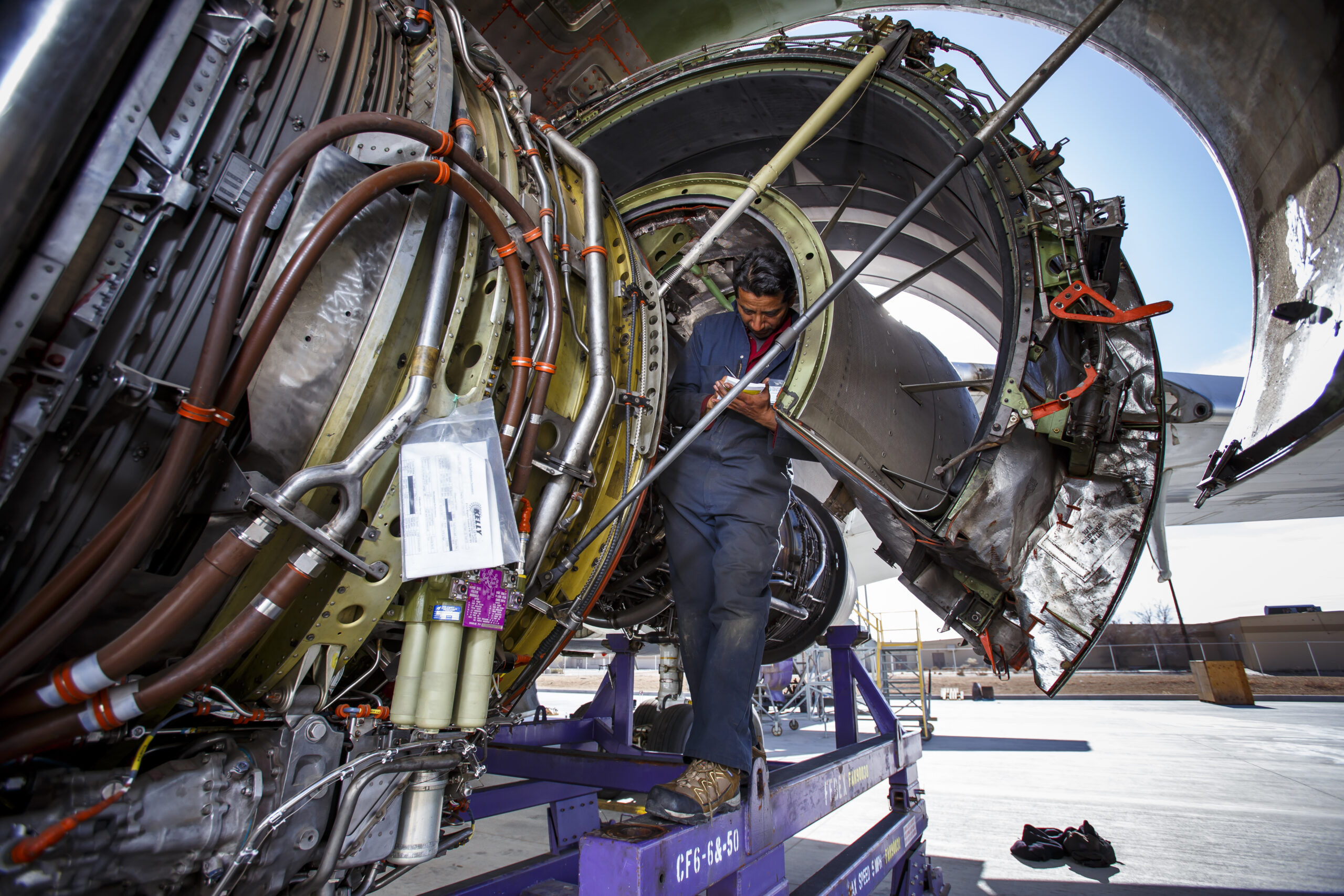

Photo Essay – Engineering highlights of the MD-10 Flying Eye Hospital in Victorville, California (2016). Photo Credit: Vero Image

“The flight schedule does affect the MRO we choose, so we schedule programs and aircraft maintenance well in advance to know where we will be and what maintenance is due to match the two schedules. Since we have the heavy maintenance scheduled for January each year we schedule programs to end and begin in the same region where we plan to do maintenance,” Johnson says, noting that this kind of planning takes place up to two years in advance.

While the work is not donated gratis, MROs “do try to give us the best price they can”, Johnson explains.

Orbis’ current aircraft is an ex-FedEx MD-10, which started its life with Trans International Airlines as the 96th DC-10 delivered off the Douglas line in 1973. It joined the FedEx fleet in 1984 and was upgraded to the 2000-era MD-10 standard of the MD-11-standard glass flight deck, gear, tyres and brakes during its service life, before being donated to Orbis in 2016. https://www.youtube.com/watch?v=2oy7BXVlXl0

While the MD-10 is on its way out from commercial fleets, Orbis expects to support the current aircraft for at least another decade and a half, with parts in good supply from many of its corporate supporters.

“One of our major donors still has 30 + MD10s in service,” Johnson explains. “We have also started to collect parts in preparation for the time when our major partner retires their MD10s. They have also notified us of their intent to donate a good supply of parts as they draw down their fleet of MD10s.”

When the Flying Eye Hospital is operational, three mechanics fly with it, both to maintain the aircraft itself and to keep the hospital modules functioning correctly.

When it’s time to get the aircraft overhauled, Johnson says, “most maintenance can be accomplished at the MRO with the hospital installed but as you can imagine there are some inspections for which the hospital will need to be removed to do that maintenance. This happens once every 6 years and we use that time to do any hospital upgrades as well as the aircraft maintenance. A heavy C check takes about 45 – 60 days where a smaller A check can take as little as a few days to a week.”

Photo Essay – Engineering highlights of the MD-10 Flying Eye Hospital in Victorville, California (2013-2016). Info – geoff.bugbee@orbis.org

Orbis uses a full modern technology suite, including online, iPad and computer-based solutions from Boeing, GE, Honeywell and other providers. With the glass flight deck upgrade to the MD-10 — adding the fruits of 1990s technology to bring what would otherwise be a legacy aircraft up to modern, technologically enabled operations — comes improvements including a modern fault self-identification system, which can assist with troubleshooting as well.

But sometimes, it just takes good old fashioned people power to keep the flying eye hospital going.

“A few years back we were in transit and landed for fuel in Muscat, Oman when we had a reversible motor pump failure,” Johnson recounts. “We could not depart without it functioning, and we did not have one aboard.”

Orbis contacted FedEx in Memphis, who found a pump in their Dubai facility. Through several other contacts, an Oman Airlines mechanic coming off work in Dubai volunteered to hand carry the part to Oman. Yet another contact cleared the part through customs and had it to the aircraft so quickly that it was back in service within ten hours of the initial problem notification.

“That,” Johnson says proudly, “is a testament to the vast amount of supporters that Orbis has around the world.”

Donating to Orbis helps to protect and restore people’s sight in some of the poorest parts of the world. If you’d like to show your support, visit https://secure.orbis.org/index.aspx to donate.

Author: John Walton

Published: 27th May 2021

Images: Courtesy of orbis.org

Join the Challenge

We are discussing this over in our Challenges area – ‘Aviation for good’ is an interesting topic – what other ways are you aware of aircraft and aviation being used for the charitable benefit of others? We’d love to hear your thoughts.