Improving wing efficiency, technology, industrialisation and production is a critical part of aviation’s future, not just for aircraft performance but to achieve aviation’s climate goals. To that end, Airbus chief technology officer Sabine Klauke and Wing of Tomorrow programme leader Sue Partridge revealed details from the programme for the first time at the Farnborough Airshow, and we were there to ask questions.

Aside from improvements in engine technology, the wings of the aircraft are the biggest lever that airframers have to pull when it comes to increasing the efficiency of flying — and, thus, reducing fuel costs and emissions as a recovering industry targets net zero.

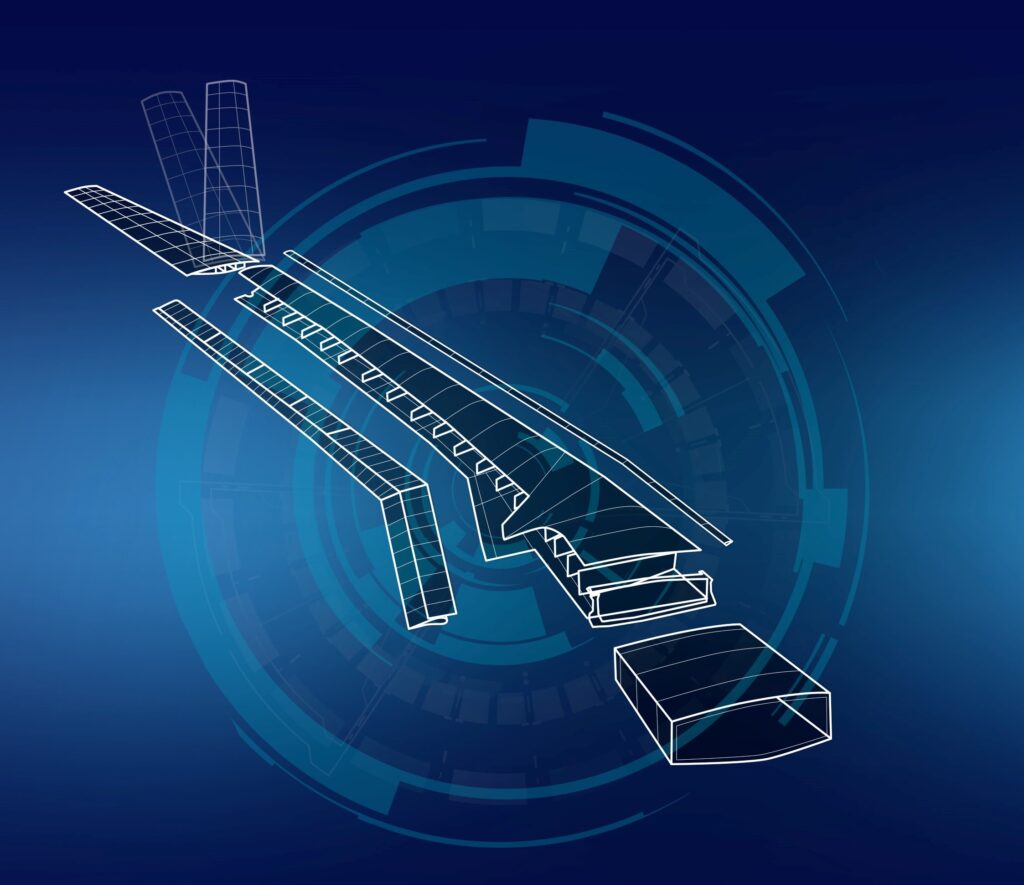

The Wing of Tomorrow programme, Airbus’ Klauke explains, is “to make the wing lighter, looking at an optimised composite design, but it’s also looking at new shapes, wider shapes”.

“Most of all,” she says, the programme focuses on “the wing itself in its design: we make it easier to assemble and focus on industrialisation.”

The Wing of Tomorrow programme itself is airframe agnostic: in other words, some of the technologies may be used in a future tranche of improvements to an aircraft already flying today. Others may be retrofittable to existing aircraft. And some may be most applicable to new airframes, especially those with different shape paradigms like hydrogen-powered aircraft.

The programme has three main objectives and three full-scale demonstrators

The first of three objectives for the programme is about improving performance: lowering drag, optimising lift, dramatically improving fuel efficiency, and very likely providing for longer wings, including possibly through folding wingtip technology.

The second objective is around cost performance, developing what programme lead Sue Partridge calls a “high-performance carbon wing, in order to achieve a weight reduction, at a low cost.” While broad use of carbon-fibre and composite structures are increasingly common in widebodies, adopting them in the narrowbody end of the market, an order of magnitude greater in volume, will require extra work.

The third objective, meanwhile, is around the technologies that Airbus needs to develop, prototype and mature in order to manufacture the wings at a rate high enough for its future narrowbody ambitions and to remove the wing as a potential bottleneck.

With Filton as its design hub (where Partridge is also head) and Broughton in North Wales as its manufacturing hub, Partridge explains that Airbus is “driving those industrial requirements upstream, so instead of designing to the design requirements, and then looking at how you might make it, we’re understanding how you’d want to make it and then really challenging the design requirements to align with that. And then we’re exploring the boundaries of what’s possible.”

“We’re a technology programme,” Partridge emphasises, “so we’re able to really push the boundaries of what might be possible. This isn’t a real wing programme. This is a technology programme, and we’re there to really understand the art of the possible.”

Support for the programme includes funding through the ATI programme and the UK Government Department for Business, Energy and Industrial Strategy. This in turn supports industrial partnerships with more than forty programme suppliers in the UK and globally, as well as work with technocentres across Europe like the UK National Composites Centre.

“The programme is focused around our three full scale wing demonstrators, or prototypes, if you like,” Partridge explains. These will examine “structural integration of the technologies, equipping, looking at the rate capability of the industrial system, and also structural test. And the milestone that we’ve reached today is that the first demonstrator has now completed its assembly.”

That first demonstrator of the three will test installation and structural technologies. The second wing is currently in assembly, and will serve as the full-scale structural demonstrator. The third is a run rate demonstrator, looking at the full industrial system, constraints of industrial technologies, and feasibility of automation packages.

The new industrial processes also eliminate the need for working within the fuel tanks.

Wing of Tomorrow is also a critical digital demonstrator

Responding to questions from Yocova, Partridge tells us that, “because Wing of Tomorrow is if you like a physical technology programme, it’s an excellent use case for us to be able to use to try out our digital capabilities. They’re working hand in hand with our DDMS team — our digital design, manufacturing and services team — to develop the capabilities like, for example, digital continuity within the design through to the manufacturing chain, looking at digital twin, understanding how you build a digital model of our assembly system in order to be able to simulate future production scenarios.”

Smarter testing is also on the cards in order to understand how to better use virtual technologies with physical testing.

“The key benefits we’re already seeing through the work we’re doing is really connecting that digital thread,” Partridge says, highlighting that Airbus is “achieving that true digital continuity of the data all the way through the process, right from the design, through the testing, through the manufacture and assembly, and also, even managing the tooling and nonconformances on the shop floor, we’re already seeing some really great benefits of that that are coming to reality.”

Looking at the wider context, we asked CTO Sabine Klauke where the Wing of Tomorrow sits in the context of Airbus’ other digital and technology programmes.

“We started this project in 2016,” Klauke tells us, “and here it is with the focus of making a step [change] in terms of lighter design, different materials, different integration work, digital chain that we test, and as a key piece as well, the industrial integration, which was in the foreground.”

“It’s completely in line with [what] we need to optimise all the components of the aircraft,” Klauke tells us. She notes that the airframer is also researching “specifically into what our next generation propulsion technologies, and so on. So [Wing of Tomorrow] is completely in this overall chain of technology research that we’re doing.”

Author: John Walton

Published 28th July 2022

Images courtesy of Airbus