In aviation’s ongoing quest to reduce its emissions and fuel burn, no stones are being left unturned — with the latest the humble auxiliary power unit, or APU, which powers aircraft when they are on the ground and not connected to ground power. At this year’s Paris Air Show, manufacturer Honeywell launched a new hardware-software combination upgrade for Boeing 737 APUs that cuts emissions, increases maintenance intervals and saves fuel. We sat down with Ray Boyd, Honeywell Aerospace’s senior director for the Large APU product line, to learn more.

While ground power can go some way towards reducing the emissions impact of aircraft on the ground, reducing APU fuel consumption — and therefore carbon equivalent — is a powerful weapon in aviation’s decarbonisation arsenal. With a new diffuser and software airflow regulator, Honeywell believes that it can cut API emissions by 1-2 percent: a solid contribution.

The upgrade, called High Efficiency Mode (HEM), “consists of an improved diffuser within the APU and the installation of a software encryption key to activate Honeywell’s proprietary software that regulates the airflow within the APU. New production 131-9A and 131-9B APUs now come from the factory with the new diffuser installed so for those APUs they only require the enhanced software to be activated,” Boyd tells us.

Honeywell estimates that some six thousand Boeing aircraft use its 131-9B APU, covering the 737NG (-600, -700, -800, -900) and 737 MAX families.

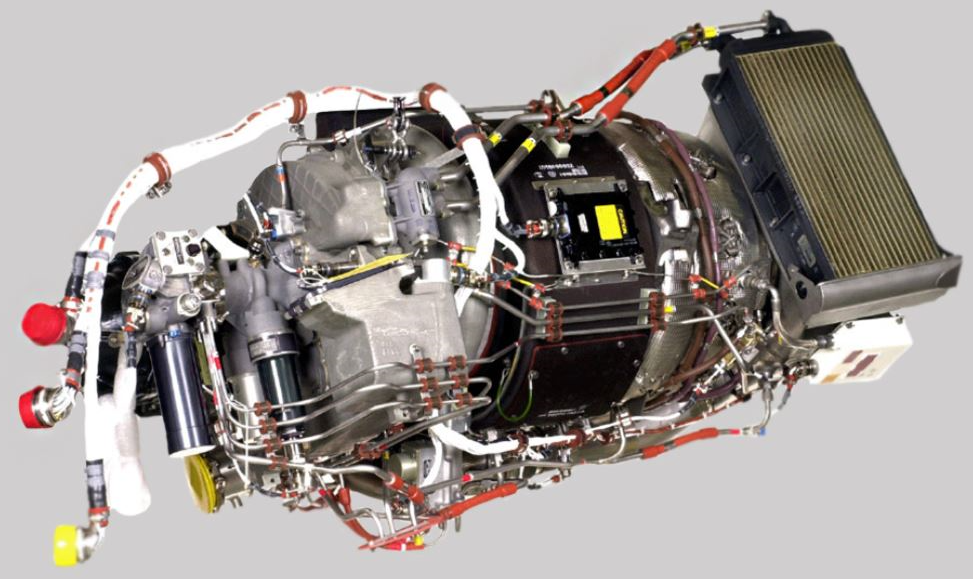

131-9B APU. Image – Honeywell

A similar upgrade rolled out for the Airbus A320 series’ Honeywell APU, the 131-9A, in 2020, and is now in use aboard over seven hundred aircraft.

On the Airbus fleet, “operation has been as expected, including a major airline carrier reporting a fuel savings of over 2.4 percent from the use of HEM on the 131-9A auxiliary power unit,” Boyd says.

As a comparison, recent research by data specialists Cirium sampled a series of flights in December 2022, and concluded that the installation of winglets on aircraft led to a fuel consumption reduction of 3.45 percent on average.

For the Airbus aircraft converted alone, “based on Honeywell estimate, the APUs on those 700 aircraft would save more than 630,000 gallons of fuel and avoid releasing 6,300 metric tons of carbon dioxide into the atmosphere during a typical year — about 1,800 APU operating hours,” Boyd explains.

The benefits from increasing deployment by an order of magnitude across the thousands of eligible aircraft are clear.

The existing electronic control unit and data memory module are retained, so the diffuser itself is the sole piece of new equipment installed into the aircraft.

“This upgrade can be installed during any regularly scheduled APU maintenance event and does not require additional downtime to implement. For future 131-9B APUs, series 49 and above, delivered with the new diffuser, the upgrade can be done via a software update while on-wing,” Boyd notes.

In addition to not requiring additional downtime, the HEM upgrade also increases the intervals between maintenance by up to 1,500 APU flight hours.

And what’s next for APUs and sustainability? “The testing and certification of the APU to perform on 100 percent Sustainable Aviation Fuel is the next step in the APU efficiency roadmap,” Boyd says. “This is forecasted to be a reality by 2030 enabling a 65 percent reduction in current emissions compared to Jet A.”

This is smart, incremental, technology-driven innovation from Honeywell, and while the overall contribution of more efficient APUs may be relatively small, earlier quick wins along the overall arc of sustainability are magnified by time — and by every new aircraft produced being that much more efficient.

Author: John Walton

Published 06 July 2023

Feature image: B737 APU – Honeywell