It’s fair to say that the aviation sector is blissfully unaware how ‘circular’ it already is – but actually we’re perfectly equipped to show others how to seamlessly implement a Circular Economy. Here’s why…

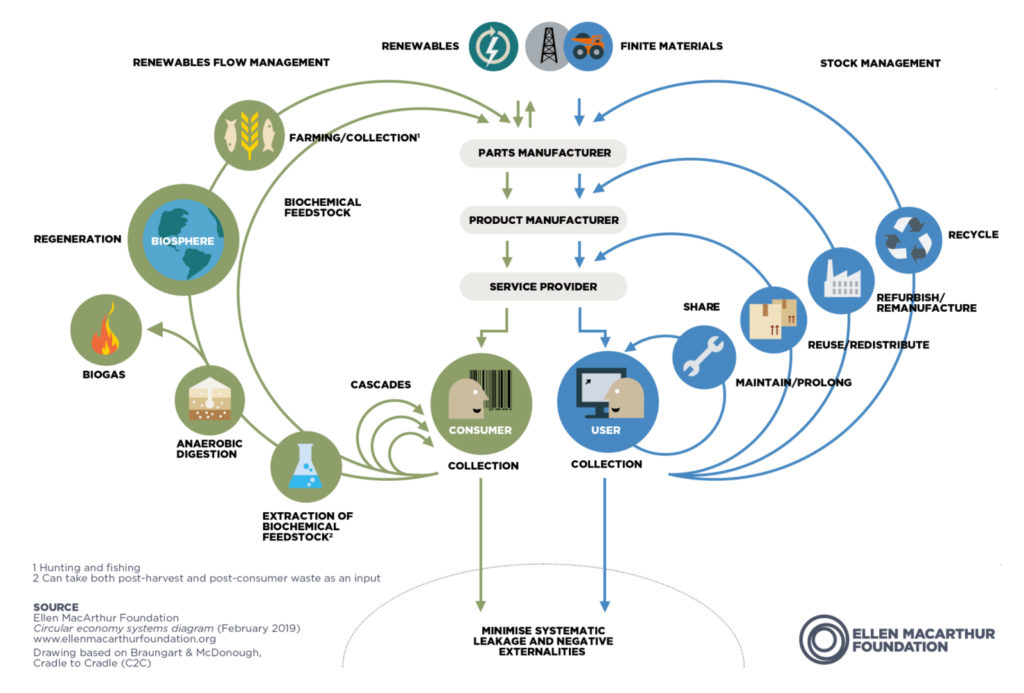

What do you know about the Circular Economy? For most, it’s not much. It’s a fairly new concept, developed by Ellen MacArthur and promoted through her Foundation. The beauty of it is in its absolute simplicity.

A pre-circular economy works on a basic three-part principle, with its heritage firmly rooted in the Industrial Revolution:

Take. Make. Dispose.

A Circular Economy challenges this ‘baked-in’ philosophy, and proposes an approach that sets out with a principled, linear-sequential mindset:

Replace. Recycle. Refurbish. Renew. Reuse. Regenerate. Reward.

Circular Economy Systems Diagram

Source: Ellen MacArthur Foundation (February 2019)

Resources are finite – therefore it is more critical than ever that we are mindful of our impact on the planet, and the pressing need to reuse and recycle as much as we possibly can. It should work in a similar fashion to the Cycle Of Life, with everything produced eventually breaking down and feeding the next round of production.

The core principle is simple, but the difficulty comes when it needs to be applied to a complex multi-layered supply chain with established and seemingly unbreakable interdependencies and deliverables between multi-organizational global ecosystems.

In simple terms, taking a Circular Approach means:

- Greener products from cleaner energy sources (we’re advancing in this area every day)

- Redesigning products for increased life and modularity

- Recovering resources from waste

- Product as a service

- Collaboration to maximise available resources

Aviation has a long way to go and a lot to do, and is working hard in that direction. In this article I just want to think about the foundations we have as an industry. About how perfect they are to build on, and how much learning we can share with other industries who are starting out on the circular approach.

Expanding on those key features of the Circular Approach (see if any of this sounds familiar):

- The customer buys a usage-based service, rather than a product

- The manufacturer delivers the service and takes responsibility for repair and replacement in a managed service

- Scrap and repair at every level of complexity is defined, managed and controlled, with repair and refurbishment being used wherever possible

- The physical product is designed so modules and sub-modules can be replaced, rather than scrapping the entire entity when it becomes dysfunctional

- Customers must return the item to approved locations to allow repair and/or replacement with component parts approved by the original manufacturer – with those parts in need of repair entering a spares pool for other equipment

- Packaging and transport of equipment is controlled and strictly managed to maximum efficiency

- The product is redesigned on a modular basis, maintaining the same core but replacing modules to improve functionality and update the product. The lifecycle is extended to years (or how about decades!) rather than months

- Specific disciplines are developed to enhance the reliability, maintainability and testability of the product, in order to maximise availability

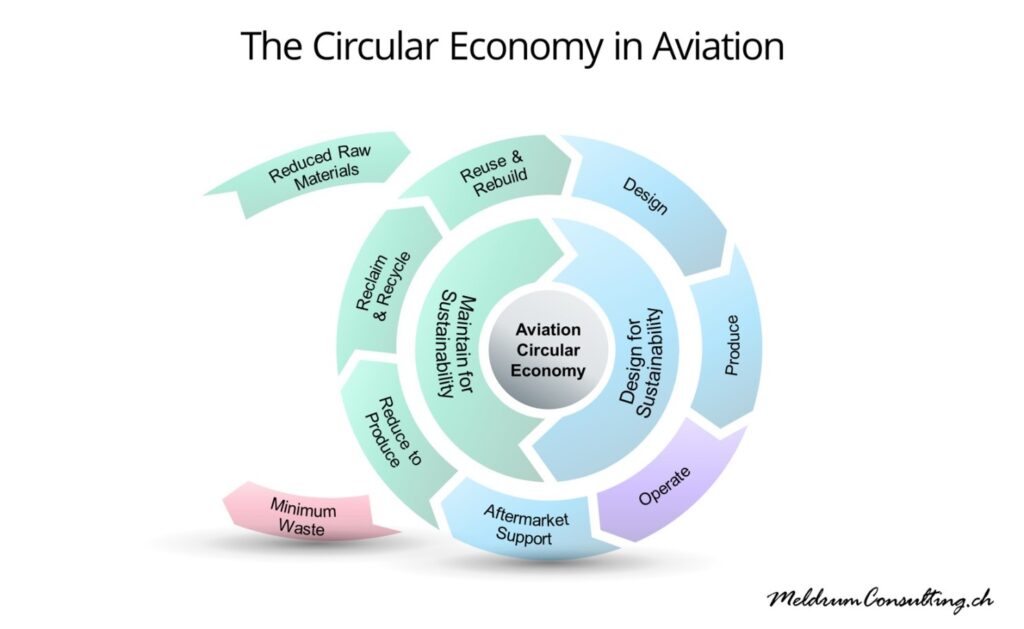

In simplified aviation terms, this is how I visualise the Circular Economy:

The Circular Economy in Aviation

Source: Meldrum Consulting

Clearly the product design and maintenance infrastructures required to enable thirty-year usage lifecycles (together with the principles we use to manage continuing airworthiness and flying hour based support contracts many organisations are using across the industry) are THE perfect foundations for a Circular Economy!

Building on our existing deep understanding of all those established practices should make it a lot easier to understand how the Circular Economy principles can be implemented, and where the real value lies.

It’s no time for complacency though these are just the foundations! We can and need to go further. I think we need to focus on the following three core principles that are absolutely key to further enhancing the circularity of our industry:

1. Further increase the adoption of managed services:

Original Equipment Manufacturers (OEMs) are passionate about getting greener.

Let’s further encourage the use of managed services, and advocate for a systemic approach to sustainability, built around the systems approach to availability – driving operations, reducing cost and increasing circularity. This principle applies from the whole aircraft level, right down to provision of coolants. We should incentivise the supplier to increase efficiency through the delivery of consumption-based (rather than material provision) services.

2. Extend ‘Maintenance Policies’ to include a more detailed and proactive ‘Scrap Policy’:

Increasing component and material reclaim (to reduce new buy) needs to be undertaken in three phases:

- Design Authority – looking in more detail at the level of repair and recertification of parts to extend recovery and reclaim that can be achieved

- Maintenance Organisation – ensure maximum repair, recovery and refurbishment is undertaken in accordance with manuals

- Drive component re-certification technology – I like to think of this as the equivalent to the 3D printing revolution. Automation and AI could help with increased recertification of piece parts. It would be greener, but would also provide the opportunity to recover additional value from scrap, if the process can become quicker, cheaper and more intelligent

3. Extent the ‘Design for Maintainability’ culture to ‘Design for Reuse’ culture:

We recently (in the last 20 years or so) made a major shift from the ‘cost plus’ to a ‘design for maintenance and support’ approach – mostly driven by the rise and availability of contracting services, and the transfer of risk to manufacturers. Building on that mentality, whilst also driving the value that can be reclaimed, is the perfect launchpad for us to reach a new objective, the ‘design for reuse’ approach.

Want to do more? Want to help take that next step?

- A good place to start is by learning more about Sustainability and the Circular Economy. The Ellen MacArthur Foundation has some great resources to explore. Check out your company’s learning resources for sustainability courses too. Also, Coursera has some great courses if you want to learn more about sustainability in your spare time

- Seek out and read your company’s sustainability targets. Let your Sustainability leaders know what you think about those targets, how passionate you are about the topic and share with them any great ideas you have to make your part of the business greener!

- Think about how you measure environmental impacts in your business unit. Do you track waste? Or maybe consumption? What about reuse? Do you know your carbon impact? Can you monitor, understand and drive improvement better in your area of the business? There’s a lot you can do!

- Feel free to contact me, I’ll help and support you wherever I can! You can find me on Yocova – search Rebecca Meldrum to find my profile page, follow me for updates in your feed, or message me directly.

Do you agree? How do you think we should improve the circularity of our industry? Do you think the aviation sector could really lead the charge on a cleaner, greener use-and-reuse approach? Is it a topic you’re passionate about? If so I’d love to hear your thoughts.

Author: Rebecca Meldrum

Published: 5th May 2022